Dissolving micropollutants into thin air

Micropollutants enter streams, rivers and lakes from consumer products such as cosmetics, cookware and textiles, but also from chemicals, pesticides and pharmaceuticals. Once they are in the water cycle, they cannot biologically degrade – i.e. with wastewater treatment plants – and gradually accumulate over time. “Micropollution is a problem everywhere,” says Dr. Silvan Staufert, co-founder and CTO of the Zurich-based start-up Oxyle AG. “They are a very insidious form of pollution. It’s also very difficult to prove.”

It is not the micropollutants themselves that are visible, but increasingly the consequences of them. “In waters downstream of sewage treatment plants, for example, 80 per cent of male fish have been found to be feminised. That’s one of the results of putting female hormones in the water. They come from medicines and agriculture.”

“Working with Innosuisse is very straightforward and practical. They look closely, but don’t create a lot of work for us as a company. With European grants, it’s more complicated.”

Silvan Staufert

Co-Founder and CTO of Oxyle AG

Completely destroying pollutants

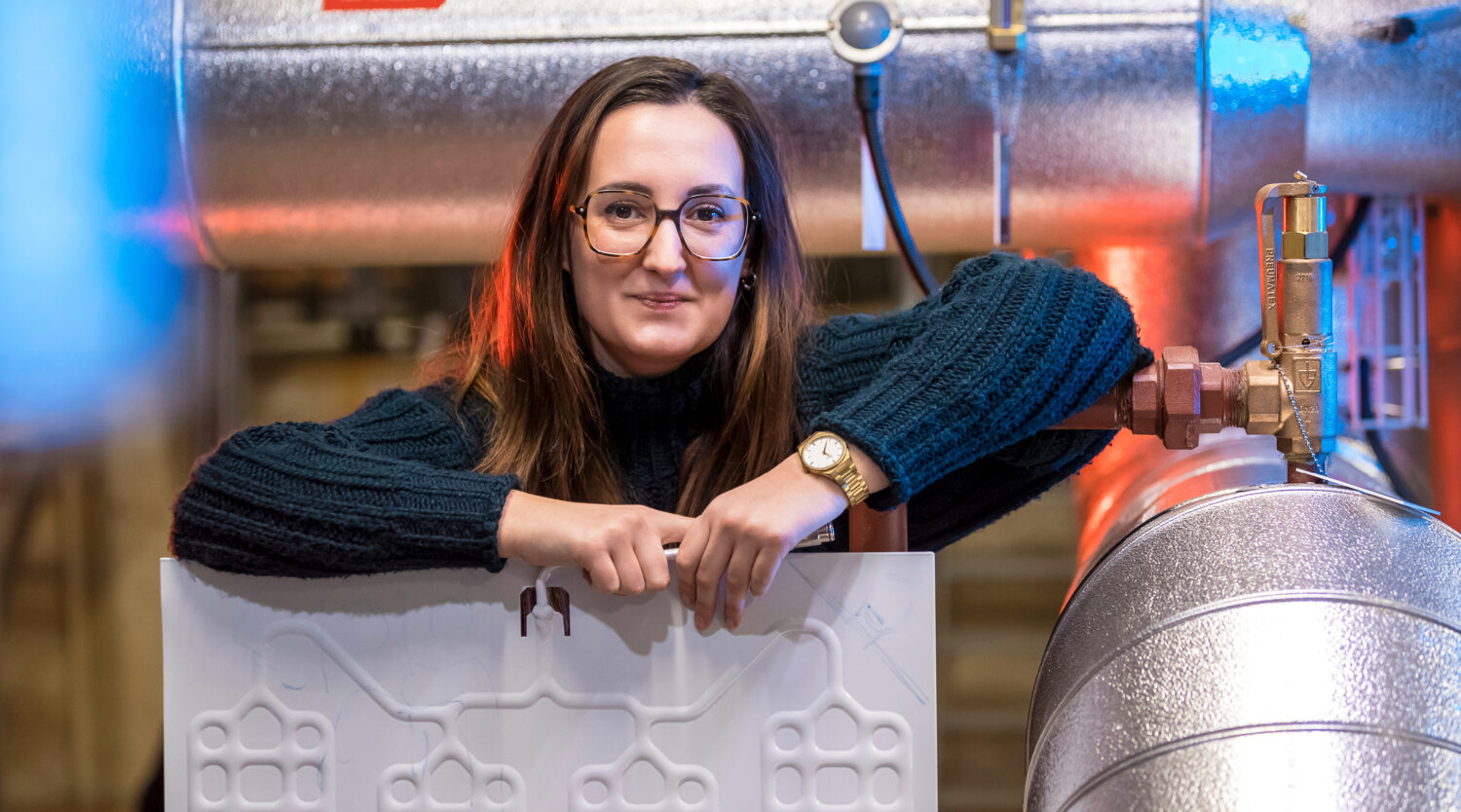

Oxyle was founded in 2020 as a spin-off from ETH Zurich and aims to tackle contaminants where they occur: in manufacturing industry – such as pharmaceutical companies or manufacturers of industrial chemicals – and in municipalities. “We want to bring the purification process as close as possible to the point of production and treat the entire water cycle on site.”

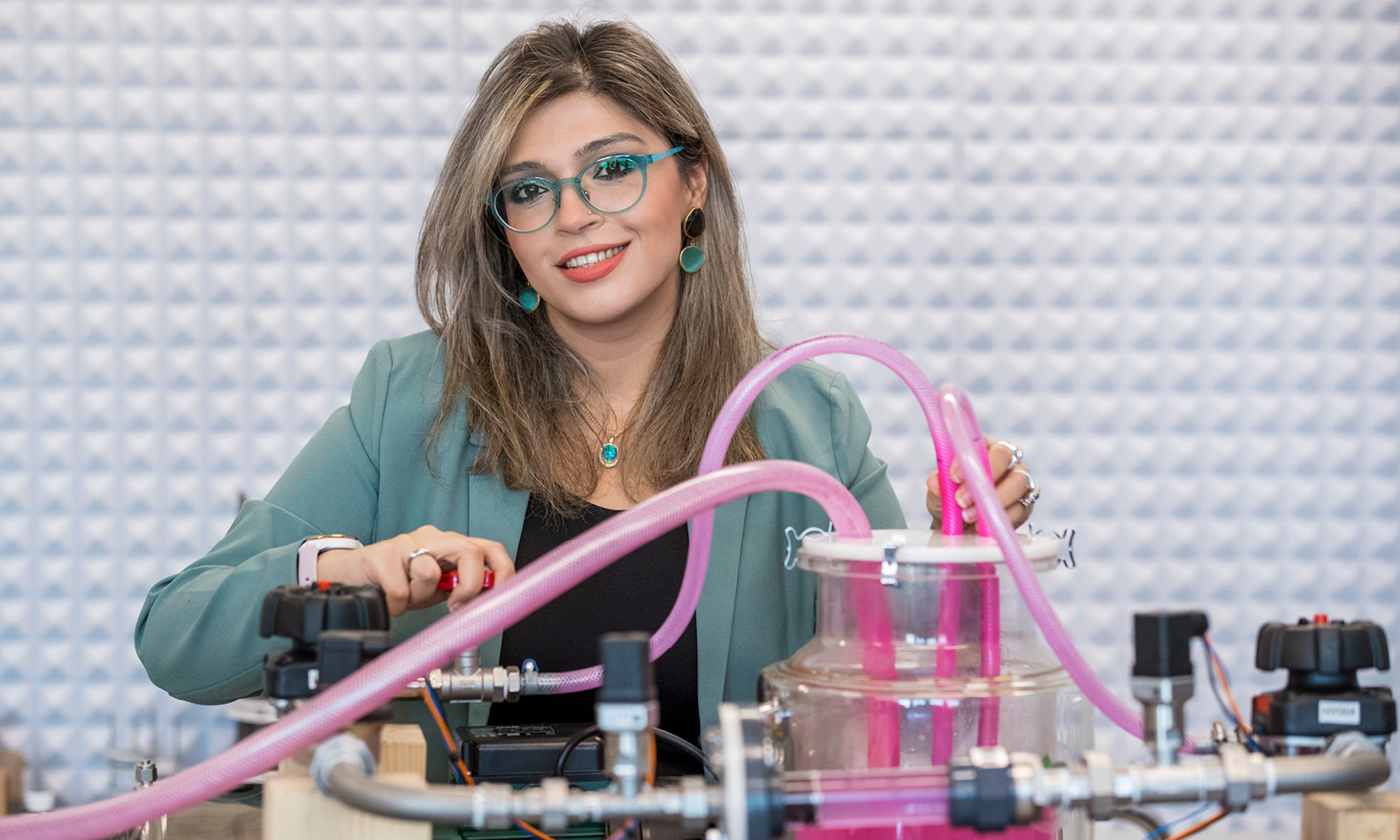

The mechanical engineer by training and his business partner Dr Fajer Mushtaq, CEO of Oxyle, have developed special catalysts that can efficiently remove stubborn and toxic pollutants from wastewater. “Our catalysts can break down over 95 per cent of the organic pollutants in water.”

Cost-effective and sustainable solution

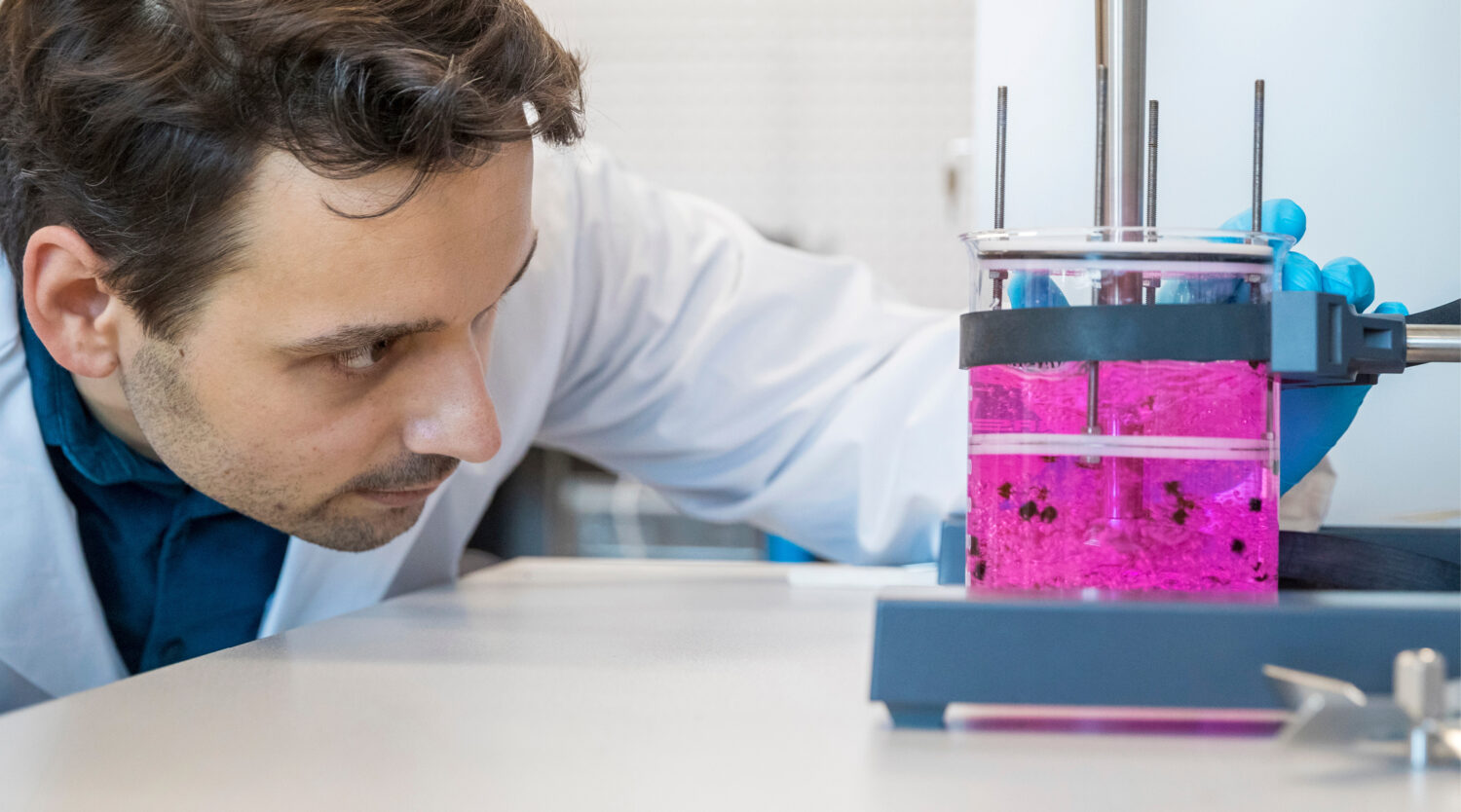

Unlike other methods, Oxyle’s catalysts do not filter micropollutants out of the water cycle, but destroy them altogether. “Our catalytic converters work just like in cars, where the catalytic converter uses the heat of the exhaust gas to destroy the pollutants in the exhaust. Oxyle’s catalyst absorbs mechanical stimuli such as vibrations and bubbles. This supplied energy starts a chemical process that destroys micropollutants. The chemical process leaves only clean water at the end and vanishingly little carbon dioxide formed during the purification process.”

The idea that impurities can be virtually dissolved into thin air is not new, Silvan Staufert stresses. “But we’ve now developed an extremely porous material that can be activated very efficiently. As a result, our catalysts have a large surface area and can destroy all types of micropollutants at once. Typical industrial wastewater is cleaned in 20 minutes. The method is efficient and easy to use.” The catalyst has an extremely long service life, according to the Oxyle CTO. “That’s why its innovation is very cost-effective and sustainable.”

Cooperation with a Norwegian company

The aim is now to develop the proven catalyst system further for larger applications – with a flow-through system. Instead of treating the wastewater in a closed tank, as was previously the case, it will now flow in a circuit. To this end, Oxyle is collaborating with the Norwegian company Biowater Technology AS and the Norwegian research institute SINTEF – in a Eurostars project.

Biowater Technology AS has developed a system for small-scale biological wastewater treatment – an important addition for the Swiss start-up: “Biowater is an interesting partner for us. We can learn a lot from an advanced company on how best to work with industry. There are also good synergies between our technologies. Many industries have both types of contaminants – biological and micropollutants. We want to continue to work together after the project is complete and provide solutions to industry and communities together.”

Looking to enter the market

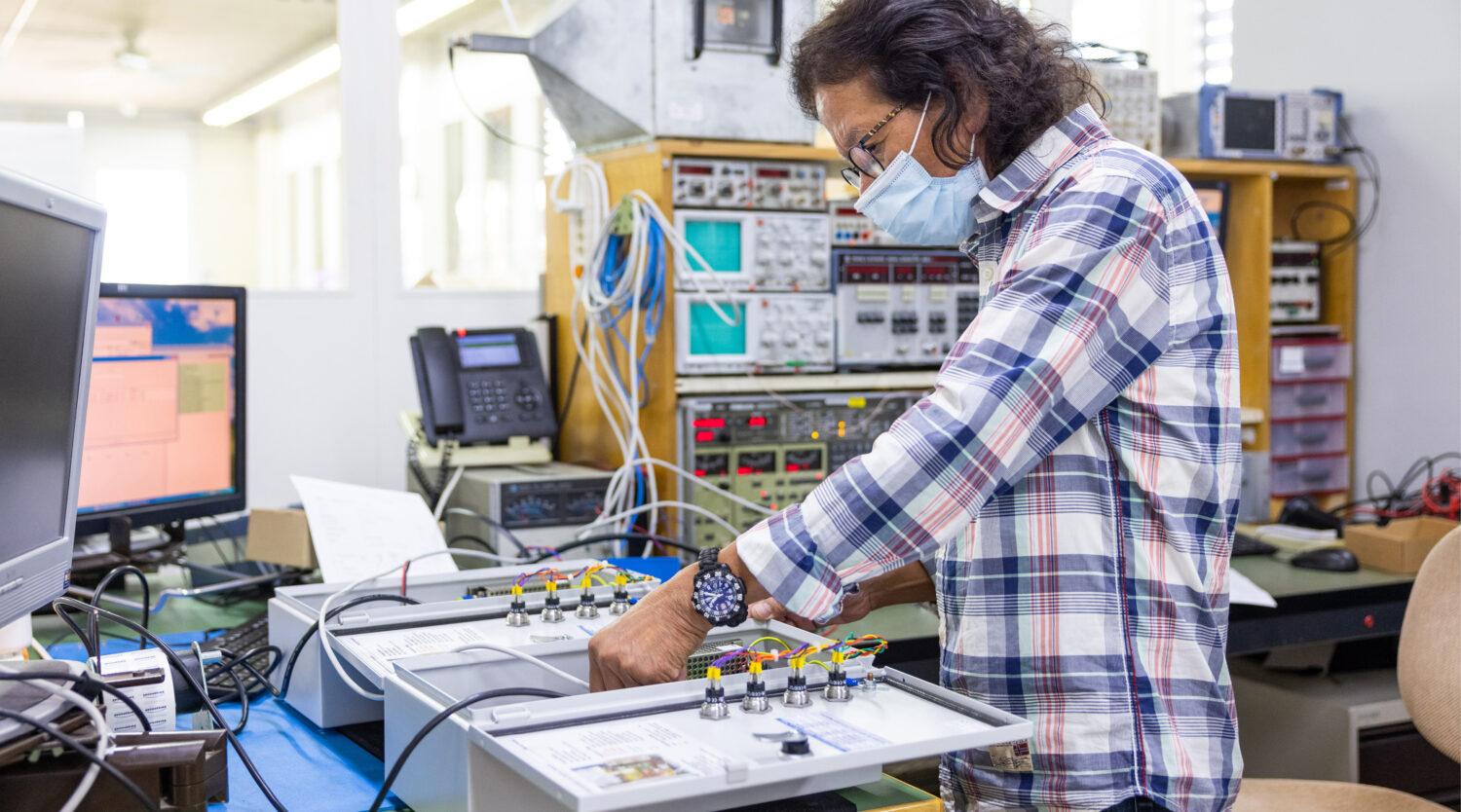

The Norwegian research institute SINTEF is helping the two partners to model the processes and optimise them through simulations. “It would be too costly for us as a small company to do this through experimentation.”

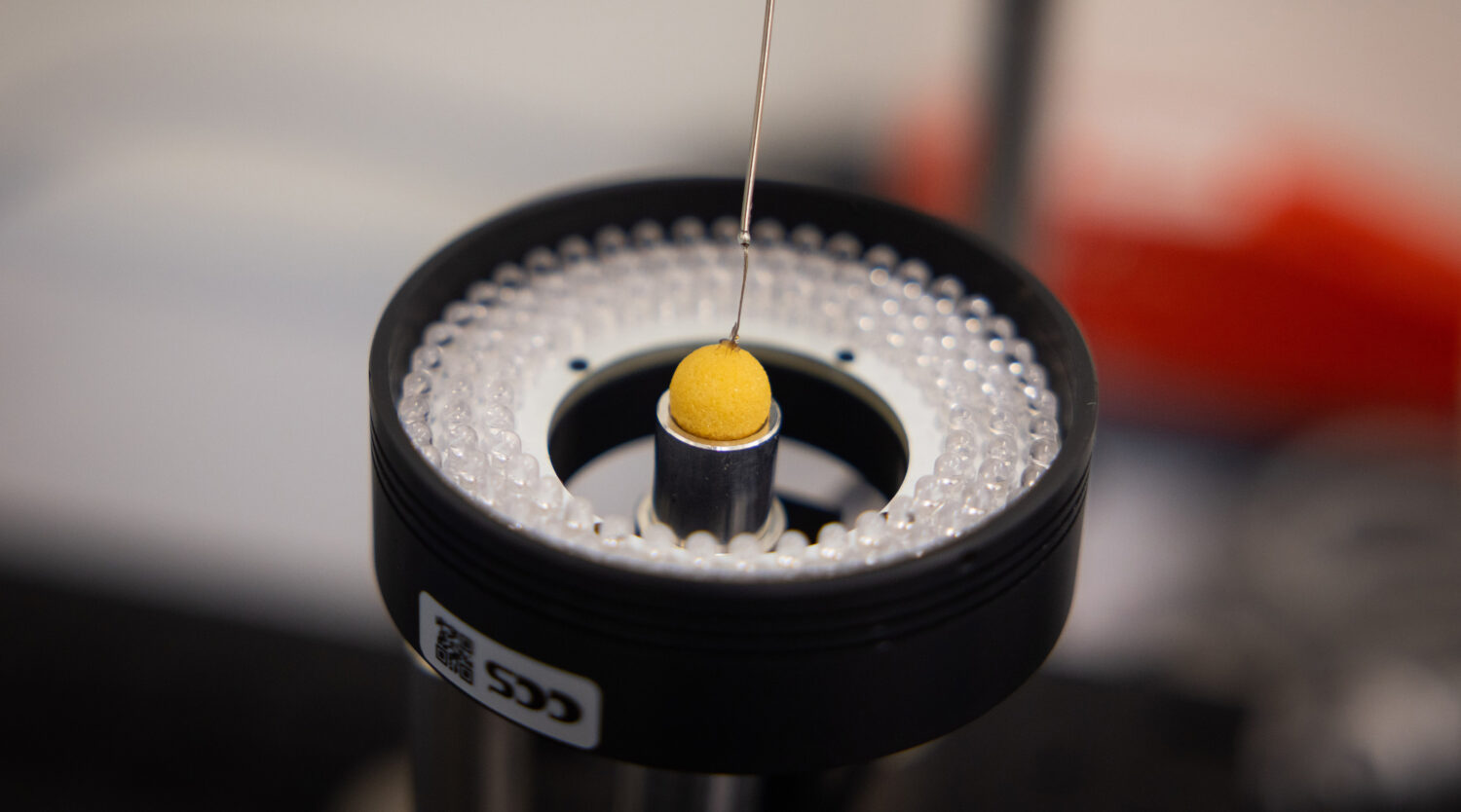

The Eurostars project is also experimenting with the shape of the catalyst, for example, with pellets that float in the water. Pumping water through the system causes the pellets to swirl in the water. This, in turn, causes them to be pressed together or collide against each other. Thus, energy is generated to destroy the impurities. “Experiments have shown that it’s an energy-efficient way to decompose pollutants.” Microbubbles formed through strong currents in the water also drive decomposition. When the bubble disintegrates, it triggers a shock wave. This activates the material in the form of the pellets.

The specific aim of the project is to produce a pilot reactor in which catalysts destroy micro and other impurities. Then there is to be a three-month trial of a biological treatment at a client’s site. “We hope this will provide the important breakthrough that will allow us to enter the market.”

No matter which market Oxyle targets first, the potential for their innovation is huge worldwide as micropollutants know no boundaries.

Step by step to an international cooperation – Innosuisse’s contribution

EEN Network: help in finding the right partners abroad

Finding the right partners internationally and growing is where the Enterprise Europe Network (EEN) helps small and medium-sized enterprises. In Switzerland, Innosuisse is responsible for providing support in the area of research, innovation and technology and links companies with the right partners – as with the Eurostars “Hydrocat” project. Working with Innosuisse is very straightforward and practical, Silvan Staufert enthuses. “The people in charge do look closely, but don't create a lot of work for us as a company. With European grants, it’s more complicated.”

Eurostars: support for an international project

For the 36-month collaboration with the Norwegian partners, Oxyle is supported under a Eurostars project. The budget for the whole project is almost EUR 2 million. Innosuisse is supporting the Swiss start-up in financing, setting up contracts and reporting.

BRIDGE: supporting the step from research into an application-led business environment

Oxyle CEO Fajer Mushtaq will be supported by the BRIDGE program of the Swiss National Science Foundation and Innosuisse for two years. The BRIDGE Proof of Concept has helped the researcher to translate the scientific results she obtained during her PhD at ETH Zurich into a practical application. It could be demonstrated that the innovative material for on-site wastewater treatment works reliably in the sewage treatment plant and that it can be produced cost-effectively and in large quantities.

Core Coaching: making the start-up fit for the market

Innosuisse Core Coaching is helping with the growth of the still young start-up and general questions about company development. “This coaching is valuable to us. Our coach Christoph Heidelberger is supporting us in our financial planning, in questions about organisational structures, how we drive milestones, how to approach investors and other areas. It’s a complete package.” The support is also very valuable in international cooperation, Staufert stresses. “Our coach has already given us tips on how to collaborate with other companies across borders and which market to target first.”

Innovation Mentoring: help with applying for a follow-up project

The start-up already has other big ideas and goals and has submitted a new project application. To do so, it enlisted the help of an innovation mentor. He helped Oxyle to successfully push through the application for the Innosuisse project.

Support from Innosuisse

- International Project: Eurostars

- EEN-Network

- Innovation Mentoring

- Start-up Coaching: Core Coaching

- BRIDGE – Proof of Concept